-

Why is stainless steel coil used in the manufacturing of photovoltaic equipment

In the manufacturing process of photovoltaic equipment, stainless steel coils have become one of the key materials due to their excellent corrosion resistance, mechanical strength, processing performance, and stability, and are widely used in equipment structural components, carriers, precision parts, and other scenarios. The specific reasons and application scenarios are as follows:

2025-07-08 -

Why are stainless steel coils used in oil and gas pipelines

The use of stainless steel coils in oil and gas pipelines is closely related to their excellent performance and special requirements for oil and gas transportation. The specific reasons are as follows: 1、 Strong corrosion resistance and adaptability to complex media environments Corrosiveness of oil and gas media: Oil and gas often contain corrosive substances such as hydrogen sulfide (H

2025-07-02 -

Why is stainless steel strip often used to make cables

Stainless steel strip is widely used in cable manufacturing, which is closely related to its own performance advantages, cable usage requirements, and adaptability to industrial scenarios. The following provides a detailed analysis of the reasons from aspects such as material characteristics, functional requirements, and industry standards: 1、 Excellent physical and mechanical properties High st

2025-06-25 -

What are the applications of stainless steel coils in the energy industry

Stainless steel coils are widely used in various energy production, transmission, and conversion equipment in the energy industry due to their corrosion resistance, high temperature resistance, high strength, and other characteristics. The following is a detailed explanation from different fields:

2025-06-17 -

Why is stainless steel strip widely used in factories

Stainless steel strips are widely used in factories, mainly due to their excellent comprehensive performance, processing characteristics, and cost advantages. The following analysis is conducted from multiple dimensions: 1、 Material performance advantages: adaptable to complex factory environments 1. Good corrosion resistance Stainless steel strip contains alloy elements such as chromium

2025-06-11 -

What are the core performance advantages of stainless steel coils

As an important form of stainless steel material, stainless steel coils are widely used in industries, construction, food and medical fields due to their unique alloy composition and processing properties. Its core performance advantages are mainly reflected in the following aspects: 1、 Excellent corrosion resistance performance Core reason: Stainless steel coils contain alloying elements

2025-06-04 -

What are the applications of stainless steel strips in automotive exhaust systems

In the exhaust system of automobiles, stainless steel strip has become the core material of key components due to its high temperature resistance, corrosion resistance, high strength, and good formability. The following are its main application scenarios and functional characteristics:

2025-05-28 -

Why are stainless steel coils used on shelves

The use of stainless steel coils (usually referring to components or plates processed from stainless steel coils) on shelves is mainly based on their characteristics of corrosion resistance, high strength, easy processing, beauty and durability, which can meet the functional and safety requirements of shelves in different environments. The following are specific reasons and application scenario an

2025-05-20 -

What are the specific differences in the use of stainless steel strips for different types of cars i

In the automotive industry, different types of cars have differences in design concepts, usage environments, performance requirements, and cost control, which can lead to variations in the use of stainless steel strips. Here are some common differences: 1. Family sedan Appearance decoration: Stainless steel strips are usually used to make body decorative strips, such as window frames, door

2025-05-13 -

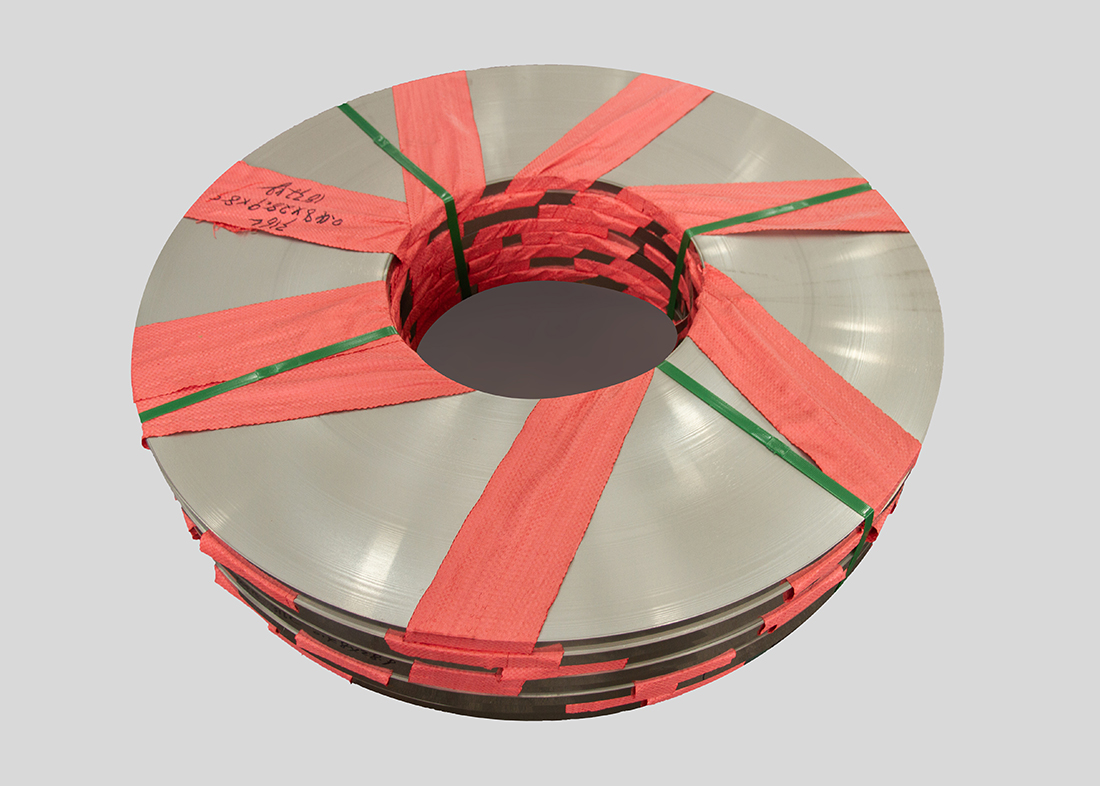

What should be noted during the transportation of stainless steel coils

During the transportation of stainless steel coils, attention should be paid to protecting their surface from damage, preventing rust, and ensuring transportation safety, as follows: 1. Packaging protection Stainless steel coils should be properly packaged before transportation. Generally, plastic film, oil paper, or specialized rust proof packaging materials are used for wrapping to preve

2025-05-06

- 12-022025

What are the applications of stainless steel coils in the engineering equipment industry

The engineering equipment industry covers multiple sub sectors such as chemical engineering, energy, construction engineering, and rail transit. Stainless steel coils, with their characteristics of corrosion resistance, high strength, and easy processing, can be processed into various structural components, containers, accessories, etc., suitable for complex working conditions of different enginee

- 11-252025

What is the cold working process for stainless steel strip

The cold processing technology of stainless steel strip refers to a series of processing procedures that change the size, shape, and mechanical properties (such as strength, hardness, toughness) of stainless steel strip through plastic processing methods such as rolling, stamping, bending, and stretching at room temperature or below the metal recrystallization temperature (usually ≤ 450 ℃), withou

- 11-182025

Why do mixing equipment require stainless steel coils

The mixing equipment uses stainless steel coils, with the core of utilizing their corrosion resistance, ease of processing, and hygiene grade characteristics to adapt to the working conditions of material mixing and ensure equipment stability. Core usage reasons 1. Corrosion resistance and adaptability to various materials: Stainless steel coils (commonly made of 304 and 316L materials) can resi

- 11-102025

How is the corrosion resistance of stainless steel coils achieved

The core of the corrosion resistance performance of stainless steel coils is the formation of a dense and stable passivation film on the surface, which, combined with alloy composition optimization and production process support, fundamentally blocks the contact between the corrosive medium and the substrate. The specific implementation logic is as follows:

- 11-052025

How to control the accuracy of stainless steel strip

The precision control of stainless steel strip is a full process management process that runs from raw materials to finished products, with the core being the control of rolling process and finishing treatment.

WeChat ID:www.80xycq.com

WeChat ID:www.80xycq.com

Add WeChat

Add WeChat

Contact us

Contact us

The phone

The phone